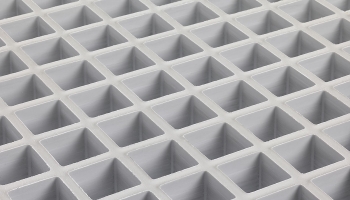

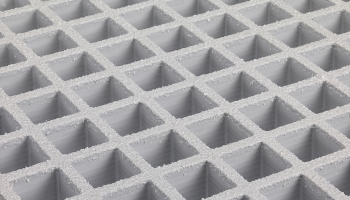

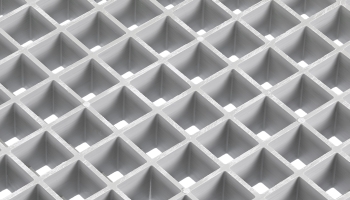

Moulded GRP-Gratings - Sandwich

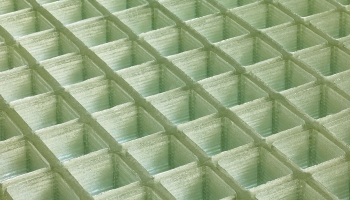

These gratings are provided with GRP plate on the surface and the bottom side of the grating. For this purpose the concave surface of the grating is grinded away and the underside is grinded for lamination connection. After that the GRP pates will be laminated to the gratings. The plate is usually 3 mm thick, but it can be adjusted according to customer wishes and statical requirements. The sandwich gratings with closed surface and bottom are better than the gratings with only closed surface when it comes to load bearing.

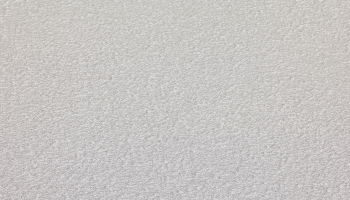

The gratings can be produced with a gritted plate or with a chequer plate look. We recommend the gritted version, as this has better anti-slip properties than the chequer plate version.

The gratings with a closed gritted surface, type GRP-SAND, achieve serration class 13 and the gratings with the chequer plate look, type GRP-SANDTR, achieve class R10.

Characteristics

- high corrosion and weather resistance

- high chemical resistance

- hygienic and resistant to bacteria

- the gratings are loadbearing in the direction of the supporting rods and the crossbars

- does not conduct electricity

- low thermal diffusivity

- Anti-slip up to R13

- relatively low unladen weight

- simple and quick on-site assemply

- high levels of comfort for walking and standing

| Model code | Height mm | Pitch mm | Mesh mm | Bar mm | Weight kg/m² | Panel dimension mm | on stock | ||

|---|---|---|---|---|---|---|---|---|---|

| SAND522-38-5 | 3+16+3=22 | 38,10 x 38,10 | 32,00 x 32,00 | 5 - 6,1 | 21,11 | 1226 | x | 2445 | |

| SAND525-38-5 | 3+19+3=25 | 38,10 x 38,10 | 31,85 x 31,85 | 5 - 6,25 | 22,84 | 998 | x | 3664 | |

| 1226 | x | 2445 | |||||||

| 1226 | x | 3664 | |||||||

| SAND525-40-5 | 3+19+3=25 | 40,00 x 40,00 | 33,75 x 33,75 | 5 - 6,25 | 22,39 | 1000 | x | 2000 | |

| 1000 | x | 4007 | |||||||

| SAND525-50-5 | 3+19+3=25 | 50,80 x 50,80 | 44,55 x 44,50 | 5 - 6,25 | 21,25 | 1277 | x | 3817 | |

| SAND530-38-5 | 3+24+3=30 | 38,10 x 38,10 | 31,60 x 31,60 | 5 - 6,5 | 25,27 | 921 | x | 3055 | |

| 998 | x | 1990 | |||||||

| 1226 | x | 2445 | |||||||

| 1226 | x | 3665 | |||||||

| 1531 | x | 3665 | |||||||

| SAND530-40-5 | 3+24+3=30 | 40,00 x 40,00 | 33,50 x 33,50 | 5 - 6,5 | 24,59 | 1000 | x | 2000 | |

| 1000 | x | 3000 | |||||||

| 1000 | x | 4007 | |||||||

| 1247 | x | 4007 | |||||||

| SAND538-38-5 | 3+32+3=38 | 38,10 x 38,10 | 31,20 x 31,20 | 5 - 6,9 | 29,62 | 922 | x | 3055 | |

| 998 | x | 1990 | |||||||

| 998 | x | 4007 | |||||||

| 1227 | x | 2446 | |||||||

| 1227 | x | 3665 | |||||||

| 1531 | x | 3970 | |||||||

| SAND538-40-5 | 3+32+3=38 | 40,00 x 40,00 | 33,10 x 33,10 | 5 - 6,9 | 29,23 | 1000 | x | 2000 | |

| 1000 | x | 3000 | |||||||

| SAND538-66-5 | 3+32+3=38 | 66,08 x 66,08 | 59,18 x 59,18 | 5 - 6,9 | 22,80 | 1196 | x | 3641 | |

| SAND540-83-5 | 3+34+3=40 | 83,30 x 83,30 | 76,30 x 76,30 | 5 - 7 | 21,30 | 1257 | x | 4007 | |

| SAND550-38-5 | 3+44+3=50 | 38,10 x 38,10 | 30,60 x 30,60 | 5 - 7,5 | 37,80 | 1532 | x | 3666 | |

| SAND550-50-5 | 3+44+3=50 | 50,80 x 50,80 | 43,30 x 44,30 | 5 - 7,5 | 31,07 | 1227 | x | 3666 | |

| SAND750-38-7 | 3+44+3=50 | 38,10 x 38,10 | 29,10 x 29,10 | 6,5 - 9 | 42,30 | 1229 | x | 3666 | |

| 1229 | x | 4007 | |||||||

| 1533 | x | 3666 | |||||||

| SAND950-38-9 | 3+44+3=50 | 38,10 x 38,10 | 27,10 x 27,10 | 9 - 11 | 50,80 | 1231 | x | 3669 | |

| SAND960-38-9 | 3+54+3=60 | 38,10 x 38,10 | 27,10 x 27,10 | 9 - 11 | 55,80 | 1231 | x | 3669 | |

The chemical resistance of the grating is determined by the resin used. The following resin versions are possible:

| Orthophal resin: | medium chemical resistance |

| Isophtalic resin: | good chemical resistance |

| Vinyl ester resin: | very good chemical resistance |