Moulded GRP-Gratings - Special designs

In addition to the known industrial application, there are many other fields of application for GRP gratings. The properties (different resins or additives) can be adapted to the intended use. For example, special resins are used for gratings in the food industry and for conductive gratings additives are added to achieve the conductivity, as GRP gratings are actually electrically insulating. In the architecture translucent and transparent GRP gratings are used. Coloured gratings are also frequently used as railing fillings or façade cladding.

Designs:

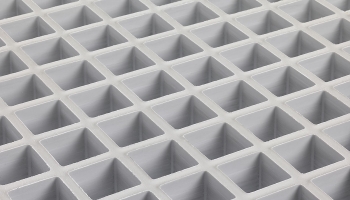

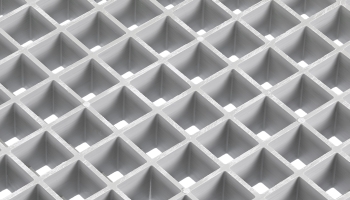

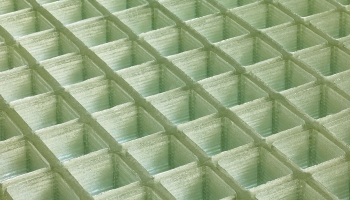

- translucent and transparent GRP-gratings

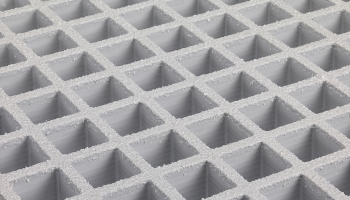

- conductive GRP-gratings for explosion proof areas

- Foodgrade GRP-gratings for the food industry

- GRP gratings as fence elements

- GRP gratings for facades

Translucent and transparent GRP-gratings are mainly used in the architectural sector. The appearance of the gratings is achieved by the fact that the resin mix does not contain any additives for fire behaviour. So it is necessary to check the requirements for fire classes when using these gratings. It should also be considered that the fibreglass layers remain visible through the optics.

Conductive GRP gratings are characterised by their suitability for use in Atex zones. Graphite and carbon are added to the resin mix to achieve conductivity. The surface of conductive GRP gratings is always sanded. The leakage resistance of our conductive GRP gratings is 10^6 - 10^8 Ohm.

Food grade GRP gratings use a special resin that has better properties for the use of GRP gratings. The gratings are characterised by good chemical resistance and good serration. Nevertheless, the gratings should not be used in direct contact with foodNevertheless, the gratings should not be used in direct contact with food.